Ever since I learned how to search for things on eBay, I've been looking for this puzzle. I know I said the same thing about the Copper Queen puzzle, but that one I found after about 10 years' hunting. This one I've been hunting for what feels like my entire online life. That would be since the late 90s, and here it is 2025. By my math that can pass as roughly 30 years(!). I tell you, the search had settled down to very occasional,... but it never really quit.

I had nothing to go on except memory. I had worked this puzzle as a teen. I had enjoyed it very much. I remembered doing that great big green tree, and the peaceful stillness of it. It was such an idyllic scene, and it had a horse in it. You know girls and horses,...

Somewhere in my college years or shortly thereafter, I picked up a poster print of Spring Morn. I don't remember the where or how, only that I had it when I got married in 1988. When we bought a house together, the first thing I did was pin up posters everywhere. This one went into the tack shop. It's been there ever since.

The print gave me the name of the artist and the idea that the puzzle which I remembered had been taken from a larger picture. No surprise with a circular puzzle, really. But there was, in fact, a surprise to come.

When I got good at online research, I eventually dug up information about Paul Detlefsen. He is not unlike Maxfield Parrish in painting Americana, but of a later generation; Parrish was born in 1870 and Detlefsen was born in Denmark in 1899. Paul Detlefsen became famous for gentle farming scenes; serenity was his trademark.

It wasn't until this phase of my search (2020) that I found out that my art print itself had been an abridgement. To my delighted surprise I found an even larger picture. I hadn't known about those trees across the river! Oh the joys of online hunting!

Ultimately I found two photos of this wonderful painting. It is not one of his most common. The careful viewer will detect that this second depiction is even wider than the first.

Maxfield Parrish may be famous for the intensity of his colors, but this print might give grounds for competition!

When I saw what I did on eBay that May day, I didn't even stop to save the pictures. You may imagine my fingers flew and I bought it very fast. The seller could've had a bad reputation for all I cared! Some things just fall into place, pre-arranged, long since decided. There are very few items I have been looking for as long as this puzzle. A book or two, a certain model horse,...( though that without any hope of affording it, hah [it's a Decorator]),... Honestly, at the moment, I can't come up with an equivalent. (cue the laugh track....) I got the pictures later.

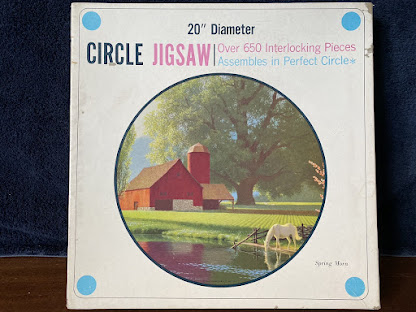

Photo from the eBay listing. I had never heard of this puzzle company, Saalfield. There was a date at the bottom of the front cover: 1965. The great age of the puzzle helps explain why I could not find it for so many years.

Working it again has been one of my most amazing puzzle experiences, akin to what I wrote about with Copper Queen, except the memories were much fainter. Also, my husband George was working this puzzle with me and he did much more of it than I'd planned on. We have done hundreds of puzzles since 2019 and we're good by now. This one still managed to be unique in its radial cut -- no other puzzle I own has that -- and its soft though firm grip despite its extreme age. Although the missing pieces were unexpected (the seller had said nothing about them), I was still so glad simply to have it that I decided they were minor. After all I have other puzzles with missing pieces,... missing a lot more than 3.

|

| Photo from eBay listing |

I have many puzzles; but this one is a very special favorite.